Water Treatment

Water treatment is used to improve the quality of the water contacting the manufactured product

(semiconductors) and/or can be part of the product e.g. beverages, pharmaceuticals, etc. In these

instances, poor water treatment can cause defective products

Corrosion

Corrosion inhibitors are designed to prevent metal loss that would otherwise lead to critical system failures in heat exchangers, recirculating water piping and process cooling equipment.

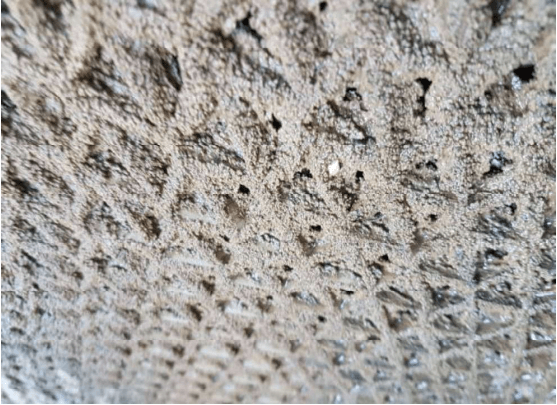

Corrosion can be present in many forms including uniform metal loss (localized or pitting), bi-metallic, galvanic, under deposit and induced corrosion. The process starts when surface irregularities, stresses, or compositional differences result in the formation of a corrosion cell {anode and cathode). Once started, corrosion at the anode causes metal to be released into the system or re-deposited locally. Pitting is particularly problematical because the local loss of metal can result in thru-wall perforation of piping and tubing.

Scale

Cooling evaporation takes away pure water, leaving behind the scale forming minerals. This requires bleeding off and replenishing of water to keep the system mineral content at an acceptable level to prevent scaling. Scale inhibitors are used to improved water efficiency and heat transfer efficiency. Scale formation, even in the slightest of forms can drastically reduce the heat transfer efficiency of these systems

Microbiological fouling:

Biological fouling of open recirculating cooling water systems results from the development and excessive growth of forms — algae, fungi, and bacteria. Each of these microorganisms is uniquely different from the other and will develop in different locations within the cooling water system. Silt, sediment, and debris in the basin of metal cooling towers provide an anaerobic environment suitable for the corrosive action of sulfate-reducing bacteria. This can result in large holes forming in the floor of a metal cooling tower basin. In addition to the destructive effect of bacterial biofilms, they can harbor pathogenic bacteria like Legionella pneumophila.

Equipment

Suppliers and installers of the following:

- UV resistant chemical tanks

- IP65 chemical dosing pumps

- Automatic conductivity controllers

- Effluent pH adjustment controllers

- Boiler auto blowdown controllers

- Softener plants

- UV sterilizes

- Filtration equipment